A space ship entering the earth atmosphere experiences intensive air resistance. That is why space capsules and shuttles have heat shielding capable to withstand high temperatures. These ceramic tiles have found their way into car manufacturing by way of the brake disc. After all: the brake system is impacted most by high temperatures due to friction.

What are ceramic brakes?

Hearing the word “ceramic” you might think of pottery. Indeed, ceramic components are in high demand in the industry. Their particularly strong insulating effect against voltage surges and heat makes them a suitable material for extreme circumstances.

Hearing the word “ceramic” you might think of pottery. Indeed, ceramic components are in high demand in the industry. Their particularly strong insulating effect against voltage surges and heat makes them a suitable material for extreme circumstances.

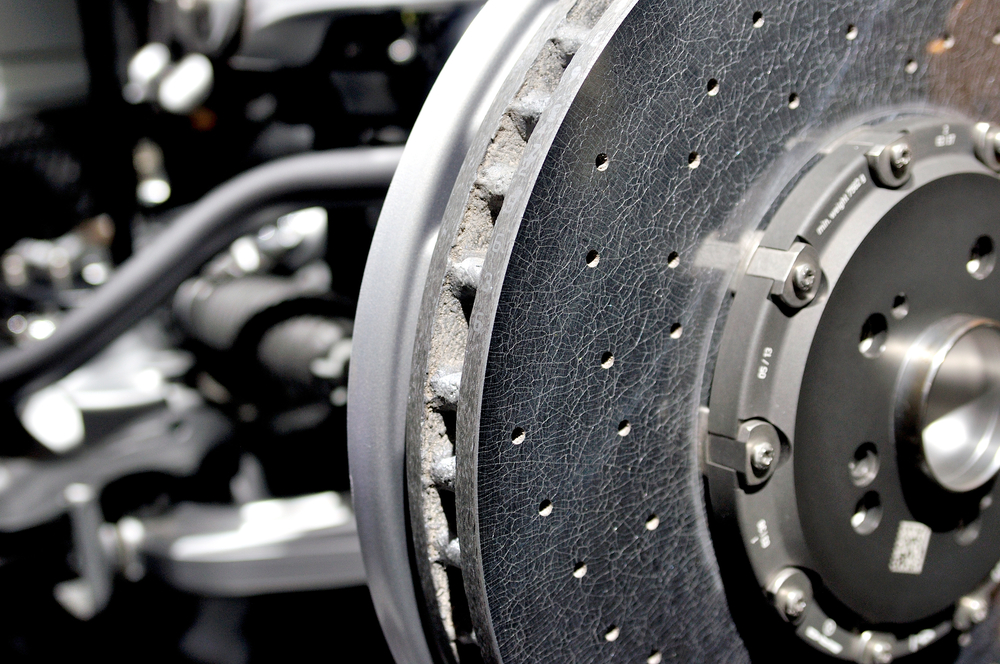

Special ceramic material is applied to brakes: a composite of carbon fibre and silicon carbide is the ideal mix for absorbing high friction energy.

Therefore, ceramic brakes are equipped with one or more components of this material, bringing advantages – as well as disadvantages.

Ideal against the fading effect

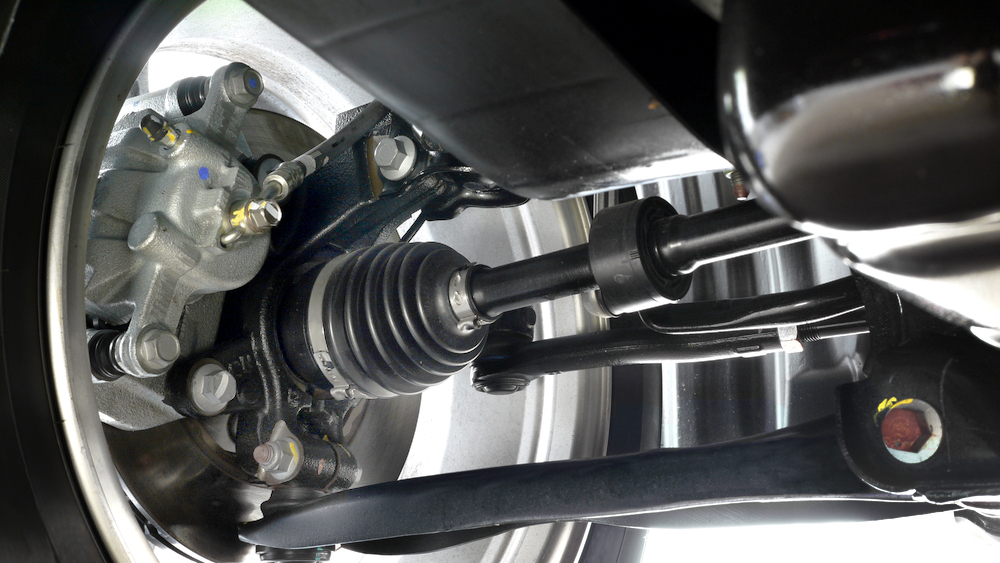

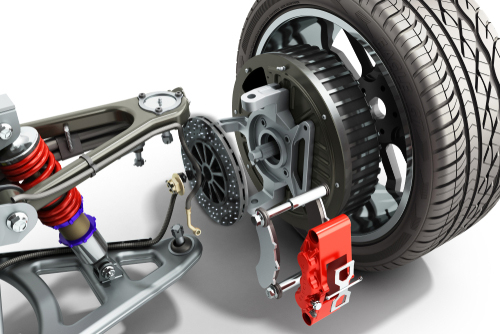

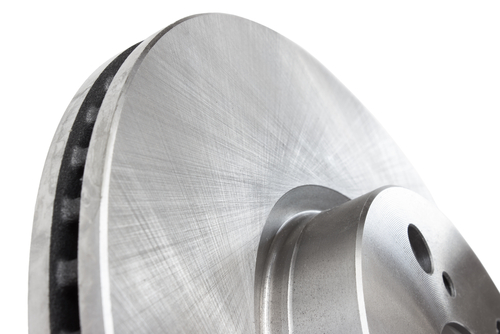

A brake on a car functions through friction. A fixed carrier with lining is pressed against a rotating element, generating friction energy, thus reducing the driving energy. The friction generates excessive heat – which could become a problem.

When friction temperature approaches the melting point of the rotating element – i.e. the disc or drum – the braking effect decreases. In the – now obsolete – brake drums this sometimes caused the total failure.

When friction temperature approaches the melting point of the rotating element – i.e. the disc or drum – the braking effect decreases. In the – now obsolete – brake drums this sometimes caused the total failure.

This is where ceramic brake discs provide a solution. Their construction material has a very high melting point which is never reached even under the most demanding driving circumstances. Not only are carbon-ceramic brake discs light and safe; at normal use, they are practically everlasting. A performance lasting up to 350.000 km is standard for these elements.

Ceramic brake discs

|

Due to their material qualities, grey cast steel brake discs are prone to corrosion. These modules depend for a great deal on their self-cleaning effect under normal driving circumstances.

Due to their material qualities, grey cast steel brake discs are prone to corrosion. These modules depend for a great deal on their self-cleaning effect under normal driving circumstances.

As a non-metallic material, carbon-ceramic composite is fully immune to salt and corrosion. The lack of flash rust and its resulting abrasion of the rust layer during braking is a key element of the wear resistance of carbon-ceramic brake discs.

Main challenge: heat dissipation

The heat generated by carbon-ceramic brake discs is no longer absorbed and therefore surrounding components are affected by the temperature. As a result of this heat development, brake hoses and sensor cables need protection by ceramic fibre insulation.

The heat generated by carbon-ceramic brake discs is no longer absorbed and therefore surrounding components are affected by the temperature. As a result of this heat development, brake hoses and sensor cables need protection by ceramic fibre insulation.

Top temperatures up to 1600°C have been measured in these modules. Ceramic brake discs require appropriate brake linings. Consequently, the replacement of steel brake discs by ceramic brake discs is a greater challenge than generally assumed.

No bargain – yet

Grey cast steel brake discs are produced by way of a pressure-cast procedure and then ground into size. When something goes wrong, the brake disc is simply melted and cast anew. Virtually no loss of material occurs in this production process.

Faulty carbon-ceramic brake discs, on the other hand, cannot be melted. They can be shredded and used as an adding agent for the building industry. However, the cheap recycling of scrap and rest material common in metal processing does not apply here.

Faulty carbon-ceramic brake discs, on the other hand, cannot be melted. They can be shredded and used as an adding agent for the building industry. However, the cheap recycling of scrap and rest material common in metal processing does not apply here.

This is one of the reasons why carbon-ceramic brake discs are so extremely expensive. To put a figure on it: a ceramic brake system can easily cost up to EUR 10.000 (± £8,800). This does not pay off even for luxury family cars. The standard installation, therefore, is reserved for limousines, sports cars, professional racing cars, CIT vans, and armoured vehicles.

The electric mobility, however, could stimulate general application. In addition to its excellent braking qualities and its extreme durability, the carbon-ceramic brake is very lightweight. In an electric car, every ounce saved has an immediate impact on its radius. Carbon-ceramic brake discs could, therefore, contribute to weight reduction. However, this is still a long way off.

The electric mobility, however, could stimulate general application. In addition to its excellent braking qualities and its extreme durability, the carbon-ceramic brake is very lightweight. In an electric car, every ounce saved has an immediate impact on its radius. Carbon-ceramic brake discs could, therefore, contribute to weight reduction. However, this is still a long way off.

The useful application of ceramics

Nevertheless, the use of ceramic components in standard vehicles is viable. Instead of replacing cast steel discs by carbon-ceramic components, installing ceramic brake linings is an adequate alternative.

Nevertheless, the use of ceramic components in standard vehicles is viable. Instead of replacing cast steel discs by carbon-ceramic components, installing ceramic brake linings is an adequate alternative.

Ceramic brake linings are available from renowned manufacturers as an accessory. They are installed in exactly the same way as traditional brake linings. Their use offers a set of advantages:

|

– improved wear resistance – less abrasion – reduction of noise development – better adhesion in case of a wet brake disc |

The braking performance of ceramic brake pads can be compared to traditional linings. Mind you, if your car is equipped with beautiful wheel rims, you are doing yourself a favour with ceramic brake linings. The dreaded abrasion tends to leave a persistent dust film, which is hard to get rid of. Ceramic brake linings produce considerably less abrasion.

The braking performance of ceramic brake pads can be compared to traditional linings. Mind you, if your car is equipped with beautiful wheel rims, you are doing yourself a favour with ceramic brake linings. The dreaded abrasion tends to leave a persistent dust film, which is hard to get rid of. Ceramic brake linings produce considerably less abrasion.

All the more amazing is the cheap price of brake sets with ceramic brake linings. Branded manufacturers offer prices for this solution which are hardly above those of traditional brake kits: an ATE brake set including brake disc, linings and accessory parts starts at ca. EUR 130 (± £115).

This is by no means excessive for an OEM quality product from an established supplier. These low prices make it worthwhile considering the choice for this feature on occasion of the next brake maintenance.

Always choose innovation

The development of brake discs goes beyond the use of ceramics. The latest development is hybrid discs: the traditional grey cast steel brake disc is riveted on an aluminium carrier. Where excellent properties with regard to even wear and heat dissipation are required, hybrid brake discs offer the full performance.

The development of brake discs goes beyond the use of ceramics. The latest development is hybrid discs: the traditional grey cast steel brake disc is riveted on an aluminium carrier. Where excellent properties with regard to even wear and heat dissipation are required, hybrid brake discs offer the full performance.

Mass is the word here: the simple, single brake discs are hardly used these days. Now, the dual ventilated brake discs have become standard on the front axle.

Unfortunately, the many advantages these innovative components offer – such as improved heat dissipation and performance – go hand in hand with added mass.

Unfortunately, the many advantages these innovative components offer – such as improved heat dissipation and performance – go hand in hand with added mass.

Nevertheless, this can be compensated for in other parts: where the heavy cast steel adds to the total weight of the car, hybrid brake discs have light aluminium. The connecting part between brake ring and wheel hub is made of light metal in high-performance brake discs.

Of course, this is only a minor contribution to mass reduction. Still, as brake discs are a critical moving mass, every weight reduction is very welcome. A lightweight brake disc causes less imbalance, sparing the complex mechanism of the steering axle.

There is no difference in quality: with respect to sturdiness, aluminium in the right alloy can now be compared to steel.

Why not the entire disc in aluminium?

Constructing the entire brake disc of aluminium is not feasible for two reasons:

Constructing the entire brake disc of aluminium is not feasible for two reasons:

|

– low melting point – not tough enough |

Aluminium melts at 600°C. A standard braking manoeuvre readily generates over 1,000 °C and therefore the light metal would fail after a few braking attempts.

And what is more: aluminium is prone to abrasion. The wear is not acceptable even when braking carefully. Using the light metal as the carrier for the brake ring is, therefore, the ultimate use of this material in a brake system.

Foto: loraks, patruflo, Chatchai.wa, Wadim Wall, Photo_works, Stason4ik, NosorogUA, M181, Sista Vongjintanaruks,n aSuruwataRi, Nneirda / shutterstock.com / shutterstock.com