Since 2001 every car with a petrol engine has an OBD2 interface (On-Board-Diagnose). Serial installation is compulsory for diesel cars since 2004. These essentially practical devices considerably simplify the search for errors and faults which is highly necessary as cars are becoming increasingly more complex.

Tracing harmful substances

It is hardly imaginable today how car engines were built until far into the 1970s: large-size fuel guzzlers contaminating the environment with leaded petrol without any filtering were standard until the early 1980s.

It is hardly imaginable today how car engines were built until far into the 1970s: large-size fuel guzzlers contaminating the environment with leaded petrol without any filtering were standard until the early 1980s.

The introduction of unleaded petrol was a hard struggle and a real revolution. Even then, exhaust gases did not become completely harmless. Instead of lead, benzene was used as an anti-knock agent, which in its turn is under suspicion of being noxious. Additionally, carbon monoxide and nitrogen oxide are inevitable components of each combustion of oxygen. Even if these pollutants can be completely filtered out, there is no avoiding carbon dioxide. Burning in the engine, the carbon-based fuel in combination with oxygen is converted to carbon dioxide. Even though this is a more or less natural substance, it is considered harmful as it fuels the greenhouse effect.

Clean combustion – technical challenge

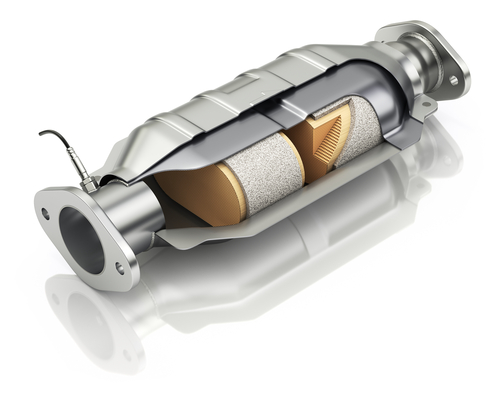

Plenty of effort is put into filtering exhaust fumes of a petrol or diesel engine as effectively as possible. Simple engine systems for reducing pollutants already existed in the era of the VW Beetle.

The unregulated catalytic converter was soon replaced by the three-way catalytic converter, which has been further developed since then. Exhaust cleaning in diesel cars is a particular challenge due to the high level of soot particles. The latest technology in this field is urea injection. This procedure is currently established in construction machinery and commercial vehicles and is furthermore increasingly used in family car engines.

The unregulated catalytic converter was soon replaced by the three-way catalytic converter, which has been further developed since then. Exhaust cleaning in diesel cars is a particular challenge due to the high level of soot particles. The latest technology in this field is urea injection. This procedure is currently established in construction machinery and commercial vehicles and is furthermore increasingly used in family car engines.

All these developments have a specific impact on the engine. What is more: already before combustion, a number of newly developed components become active. Exhaust gas recirculation, intake air cooling, adjustments of ignition management and many more are intended to prevent the development of noxious substances. Generally this works pretty well.

Complex systems, vulnerable systems

The problem with sophisticated exhaust filtering systems lies in their susceptibility to malfunctions. Each fault has a double effect, possibly causing an escalation:

The problem with sophisticated exhaust filtering systems lies in their susceptibility to malfunctions. Each fault has a double effect, possibly causing an escalation:

1. The faulty component can no longer perform its task.

2. The control unit receives faulty data and can no longer function correctly.

In order to avoid permanent excessive pollutant emission or the mutual destruction of engine components, a monitoring system was introduced. Permanent error control enables the control unit to react to malfunctions before more serious damage occurs. The computer cannot repair a faulty component. This requires the assistance of the operator. For him to know where to look for an error, OBD was developed.

OBD2: Open, accessible, practical

Reading an error memory used to be a mysterious process, only possible with expensive special tools. Garages charged substantial fees for this step before even loosening one single bolt. Today, the on-board diagnostics with extremely inexpensive solutions are accessible to everyone. This is made possible by the strict standardization of the OBD2 components.

Reading an error memory used to be a mysterious process, only possible with expensive special tools. Garages charged substantial fees for this step before even loosening one single bolt. Today, the on-board diagnostics with extremely inexpensive solutions are accessible to everyone. This is made possible by the strict standardization of the OBD2 components.

The shape of its connection plug, its location and the type of error codes are stipulated by law. The flat, double-row standard plug for connection to a diagnostic unit must be situated in the driver’s operational area. Generally the plug connection is located under the steering wheel or on the left side of the fuse box. A look in the service manual provides accurate information. Every compatible device is compatible for connection. Individual initiatives by vehicle manufacturers, as they were still possible with OBD-1, are no longer permitted.

The standardized connections and error code values have dramatically reduced the price for diagnostic devices. Only a few years ago, devices cost several hundred euros. Nowadays, high-performance handheld devices are available for less than 50 euro.

The trick is: A large part of the required computing as well as display options are provided by the driver himself.

Devices are good, wireless switches are better

Traditional equipment for reading the fault memory is still available, although it got superior competition: the smartphone or tablet. All these widely available standard devices need is an interface with the control unit and the corresponding program. This interface is a plug, which is easily obtainable in excellent quality for only 20 – 30 euro.

Traditional equipment for reading the fault memory is still available, although it got superior competition: the smartphone or tablet. All these widely available standard devices need is an interface with the control unit and the corresponding program. This interface is a plug, which is easily obtainable in excellent quality for only 20 – 30 euro.

Caution when buying something at the specialist retailer – The devices offered by free platforms are often counterfeits sending faulty signals or none at all.

The plug-in module is plugged into the connector on the vehicle’s OBD2. Now all the smartphone needs is the corresponding app, available at low cost or even completely free of charge – now you can see if there is something wrong with the car.

Generally it is safe to assume that every manufacturer of wireless plug-in modules offers his own app. The more sophisticated the used device, the cheaper its app. Professional connectors costing more than a hundred euro often come with an app free of charge.

Generally it is safe to assume that every manufacturer of wireless plug-in modules offers his own app. The more sophisticated the used device, the cheaper its app. Professional connectors costing more than a hundred euro often come with an app free of charge.

The real advantage of the app-smartphone solution in comparison to the traditional systems is the fact that it is always up to date. The apps are permanently updated. You always have the latest version available with just a few clicks. In traditional systems an update of the operating system is either impossible or very complicated.

OBD2 Error codes and how to read them

The OBD2 error codes are shown as a combination of letters and numbers.

The letter comes first, followed by a four-digit number.

The letters signify:

|

P – drive |

It doesn’t say, what the actual malfunction is. The letter gives a general idea.

The four-digit numbers signify:

|

1. Digit: 0 = standard code; 1-9 = Vendor-specific code |

3. and 4. Digit: Exact description of the component

| Example: The error code P0400 means: P: The error is located in the drive |

Car Electrics Discounterlimited offers!Order online ⇒ |

How to work with the OBD2 module

Regardless of whether the complete device or the plug-in app solution is used, the procedures for error reading are the same.

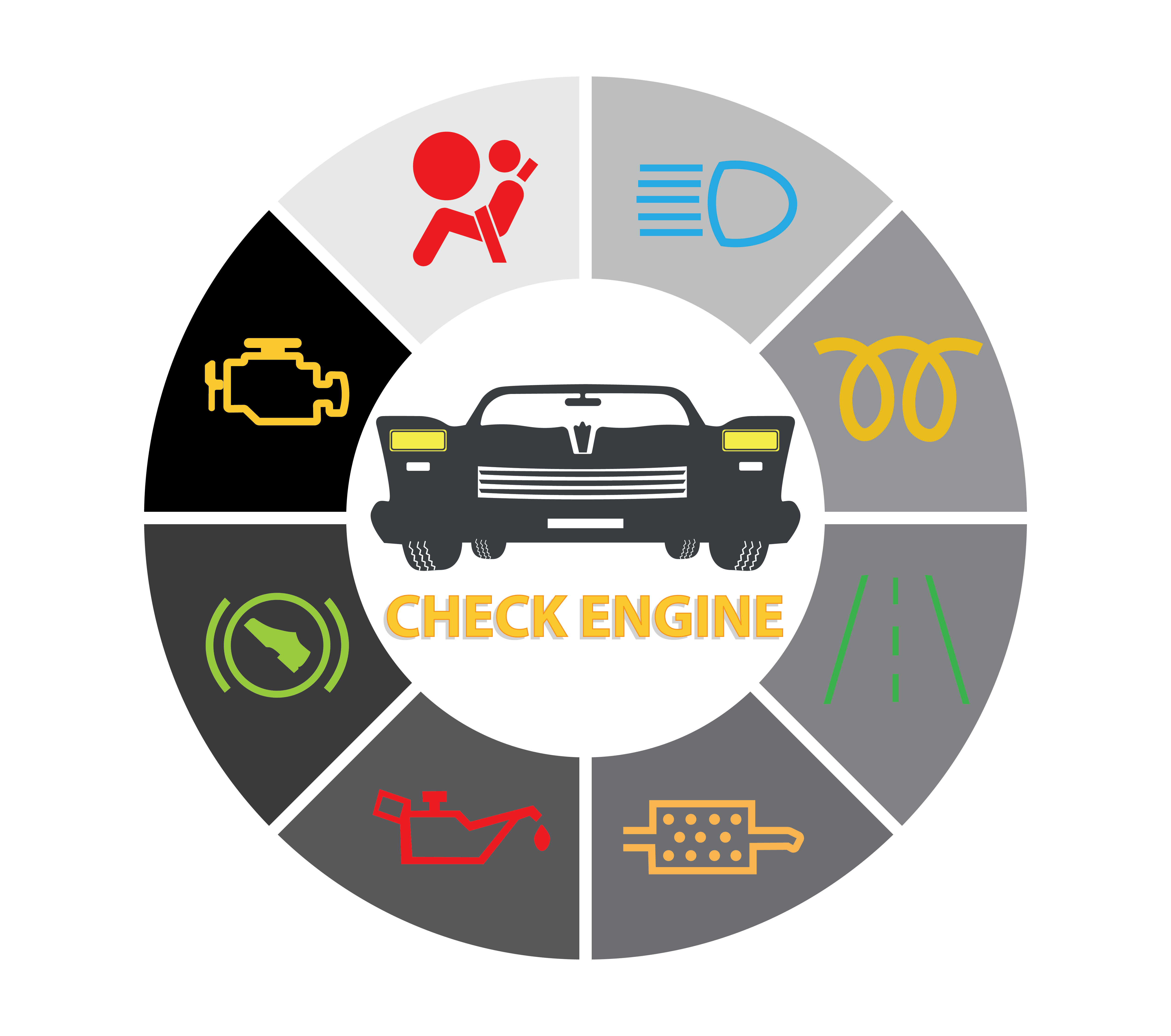

1. The check engine light switches on

|

2. Connecting the plug-in module

|

3. Run diagnostics

|

4. Carrying out repair

|

5. Delete the fault memoryUpon repair the error memory is deleted. The app menu guides the user to the desired function. With just one click the error memory can now be cleared. |

Foto: Khakimullin Aleksandr, rumruay, Mi Pan, vladwel, Stanisic Vladimir, mattcabb, Matt Howard, uleiber, Jenov Jenovallen, Slavoljub Pantelic, Aboltin, Mihalex / shutterstock.com

The check engine light is a general indication of something being “

The check engine light is a general indication of something being “ If the check engine light indicates a fault, connect the plug-in module to the OBD socket. The plug-in module must be switched on.

If the check engine light indicates a fault, connect the plug-in module to the OBD socket. The plug-in module must be switched on. The diagnosis does not start automatically, but is initiated via the app or the programming. After a few seconds of CPU time the error code is displayed. In addition, a log is created, providing information on all systems.

The diagnosis does not start automatically, but is initiated via the app or the programming. After a few seconds of CPU time the error code is displayed. In addition, a log is created, providing information on all systems. The car’s maintenance documents show how to replace or repair the faulty component. Since the OBD2 always depends on the car’s sensors, it is always advisable to check these meticulously. Often, even minor cable ruptures or

The car’s maintenance documents show how to replace or repair the faulty component. Since the OBD2 always depends on the car’s sensors, it is always advisable to check these meticulously. Often, even minor cable ruptures or

(8 votes, average: 3.50 out of 5)

(8 votes, average: 3.50 out of 5)