Accident statistics speak for themselves: even today, despite laws and available tools, up to 20% of all accidents are due to inadequate load securing. With a bit of knowledge and a sense of responsibility every cargo can be safely constrained. Read in this overview about the basis, legal situation and the best means of safely securing cargo for transported materials.

Inertia of mass

Force equals mass times acceleration. Once in motion, a mass maintains its direction. In order to change its direction, high forces must be applied. Mass will counter this with equal force. Dynamically moving a mass through several changes of direction requires considerable effort.

Force movement in cargo transport

This becomes obvious when looking at the movement of a load during transport. Accelerating from a stationary position the vehicle slightly lowers at the rear as a result of the load exerting a force countering the movement direction and pulling it the other way. When driving through a curve the vehicle swings outwards. The mass wants to go straight ahead, pulling in the original direction of the car. When braking the vehicle lowers at the front axle. The load wants to continue the driving direction, affecting the front suspension.

This becomes obvious when looking at the movement of a load during transport. Accelerating from a stationary position the vehicle slightly lowers at the rear as a result of the load exerting a force countering the movement direction and pulling it the other way. When driving through a curve the vehicle swings outwards. The mass wants to go straight ahead, pulling in the original direction of the car. When braking the vehicle lowers at the front axle. The load wants to continue the driving direction, affecting the front suspension.

Brake discs in Top qualitycheaply up from £7,85Go to shop ⇒ |

A lot more happens within the vehicle: the lashing straps, nets, ropes, bolts and everything else used for load securement absorb movements of the load, safely transmitting them to the suspension. At least ideally. Practically, the load securing is often ignored at risk of a fine.

Lid is closed – all safe now? Wrong!

Many transporters act according to principle: all is well in the boot. Goods cannot fall from the loading surface through the outer walls and therefore the load is sufficiently secured. This is not the case. Shifting cargo can cause dangerous situations, such as:

Many transporters act according to principle: all is well in the boot. Goods cannot fall from the loading surface through the outer walls and therefore the load is sufficiently secured. This is not the case. Shifting cargo can cause dangerous situations, such as:

– skidding and swerving

– overturning

– penetration of partitions

– penetration of doors

– Denting of the driver cabin in case of emergency stop.

Regardless if all this, unsecured load will certainly sustain damage in an enclosed space. It is therefore essential to safely strap and constrain all goods.

Always according to type of cargo

The choice of load securing is always connected to the type of load. Different types are:

– fluids

– bulk material

– general cargo

– sensitive cargo

Fluids in large quantity are ideally transported in a tank truck, the simplest way to secure liquids. Nevertheless driving with a large tank is a challenge, particularly if the tank is not filled up to capacity. Sloshing fluids can be hazardous, especially when driving quickly through a curve.

Fluids in large quantity are ideally transported in a tank truck, the simplest way to secure liquids. Nevertheless driving with a large tank is a challenge, particularly if the tank is not filled up to capacity. Sloshing fluids can be hazardous, especially when driving quickly through a curve.

Bulk material is much easier to handle. A loose, dry mass always generates friction forces in the interior. Sand, granulate, grit, scrap or screws – the individual parts interlock, preventing sloshing like fluids do. Nevertheless, bulk material can move in case of sudden load change. Then, transporting a dry mass becomes a problem: contrary to fluids bulk material does not level out quickly. In the worst case, the vehicle can lose its balance and tip over.

Bulk material is much easier to handle. A loose, dry mass always generates friction forces in the interior. Sand, granulate, grit, scrap or screws – the individual parts interlock, preventing sloshing like fluids do. Nevertheless, bulk material can move in case of sudden load change. Then, transporting a dry mass becomes a problem: contrary to fluids bulk material does not level out quickly. In the worst case, the vehicle can lose its balance and tip over.

General cargo is everything that can be stowed on pallets, in cartons, boxes or separately on a loading surface. General cargo requires adequate load securing. This especially applies to sensitive loads. Nowadays, many different lashings and straps are available, considerably simplifying safe transport of even the most fragile material to its destination.

General cargo is everything that can be stowed on pallets, in cartons, boxes or separately on a loading surface. General cargo requires adequate load securing. This especially applies to sensitive loads. Nowadays, many different lashings and straps are available, considerably simplifying safe transport of even the most fragile material to its destination.

- The logistic sector offers different vehicles enabling safe transport of almost any cargo. The most common vehicles are:

– Open low-load trucks for the transport of large single items.

– Open tipper trucks for bulk material.

– Tank trucks for liquids.

– Platform trucks for general cargo, containers or single items.

– Box trucks or vans for general cargo with special protection requirements.

– Trucks for special transport.It is always important to choose the right truck for the cargo. You could of course try transporting water in a tipper truck. Question remains how much of it reaches its destination. Or you could try filling a box truck with sand – provided you found a way of adequately unloading the cargo. Fortunately logistic suppliers have the right containers, trucks and load securing available.

Cargo securing for everybody

The following products are common for cargo securement:

– lashing straps

– chains

– bolts

– nets and tarpaulin

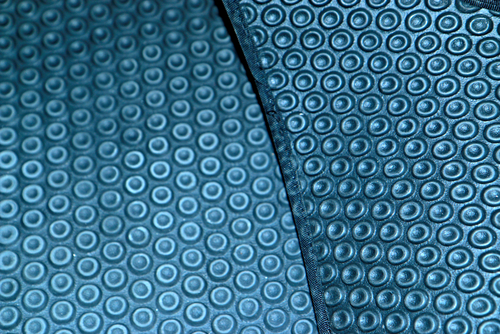

– anti-slip mats

– barriers

These products keep the cargo in its place in a friction-locking and form-locking manner.

- Friction-locking signifies the cargo being secured by making use of forces. If a lengthy piece of cargo is secured by transversely tensioned lashing straps, friction-locking as well as form-locking are provided. The friction-locking works in the longitudinal direction: the pressing force of the tensioning straps and the friction of the underground – ideally supplied with anti-slip mats – prevent the cargo from shifting. On its side the physical barriers of the transversely tensioned lashing straps secure the cargo. In order to fall sideways from the loading surface, the load must first break through the lashing straps.

- Lashing straps are the most common means of securing cargo. There is a wide variety of securement available. The choice varies from light, though robust lashing belts for a roof rack to broad and very stable lashing straps for heavy cargo. Machines and even large-size steel tubes can reliably be secured with lashing straps. Loads projecting more than one metre require a red warning flag, preventing drivers from crashing into the protruding cargo.

- For really massive cargo, chains are superior to straps, although considerably more difficult to handle.

Still, chains promise maximal security.

- For special transports a direct fastening of the cargo on the loading platform is necessary, generally requiring special constructions. In those cases the truck is often exclusively equipped for its particular cargo. These solutions are often found in machine and vehicle construction. This has the advantage of reaching maximal load securement with bolts and barriers. Furthermore, these solutions enable quick loading and unloading.

- Nets are simple, yet effective tools for preventing loose and light loads from flying away. They are often installed on open trucks or rubble containers. The more granulated the cargo, the finer the net’s meshes should be. Maximum securement is offered by tarpaulin, additionally providing protection against the weather.

Barriers can be inserted or turned up, preventing the cargo from shifting and offering additional attachment points for lashing belts.

Barriers can be inserted or turned up, preventing the cargo from shifting and offering additional attachment points for lashing belts.

Flexible barriers maximise the utility of low-load trucks, platform trucks or box trucks.

Load securing: Mind the centre of gravity

Load securing starts with effectively spreading the cargo over the loading platform. The cargo is spread out in such a way that the centre of gravity is the most central point on the loading platform.

Load securing starts with effectively spreading the cargo over the loading platform. The cargo is spread out in such a way that the centre of gravity is the most central point on the loading platform.

For one-axle trailers this is particularly important. If the centre of gravity lies too far to the rear, the trailer lifts up the rear of the towing vehicle via the drawbar. If the centre of gravity lies too far to the front, the drawbar presses the rear axle of the towing vehicle downwards, lifting its front wheels. Both axle loads are awkward and considerably compromise safe driving. Swerving cannot be avoided.

Important is also: always load and unload one-axle trailers when they are coupled to the towing vehicle. The drawbar and the towing vehicle prevent the trailer from tipping to one side.

Towbar discountsAvailable nowOrder now ⇒ |

Doing without securement is an option

Large quantities of general cargo can be transported without additional load securement. If general cargo such as cartons on pallets can be tightly fitted in a stable loading area, additional lashing is not necessary. The cargo, however, has to be unloaded entirely. As soon as hollow spaces occur within the load it may shift, making additional load securement necessary.

Large quantities of general cargo can be transported without additional load securement. If general cargo such as cartons on pallets can be tightly fitted in a stable loading area, additional lashing is not necessary. The cargo, however, has to be unloaded entirely. As soon as hollow spaces occur within the load it may shift, making additional load securement necessary.

Foto: S_Photo, lassedesignen, Rob Wilson, Kletr, ksl, Andrey_Popov, SARIN KUNTHONG, Serjio74, Zerbor, Ekkaluck Sangkla, CL STUDIO, Andreas Alexander, kang hyejin, Abraham Badenhorst / shutterstock.com

(8 votes, average: 3.50 out of 5)

(8 votes, average: 3.50 out of 5)