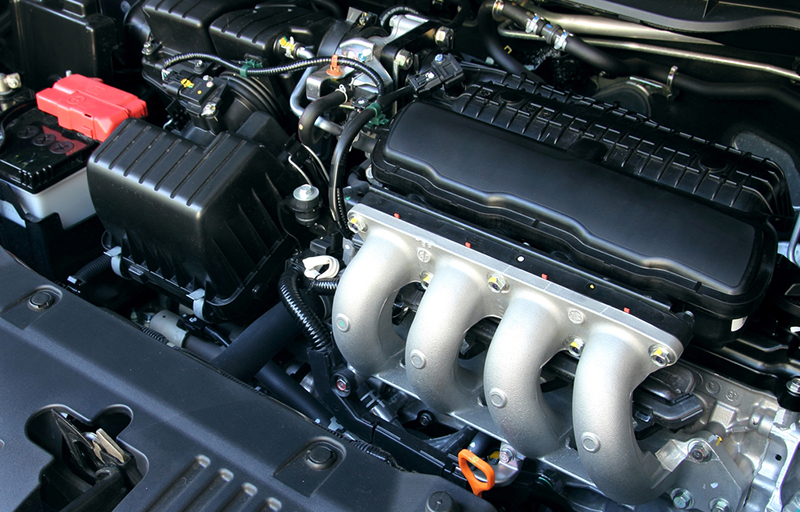

Today, supplying an engine with air has become a real science. Where once an intake pipe with air filter was sufficient, today a complex assembly with a multitude of components is used. In the case of a defective intake manifold, this can become noticeable primarily through loss of performance, heavy contamination, and oil leakage.

The main reason for this increase in complexity is modern engine management with exhaust gas aftertreatment. Engines today are supplied with air via intake manifolds (another term is “intake plenum”). But when the complexity of the technology goes up, so does the risk of defects.

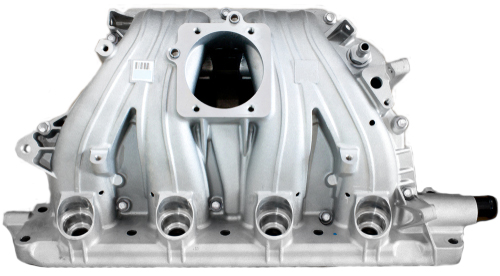

Structure of an intake manifold

An intake manifold consists of a solid tubular casting made of aluminium or grey cast iron. Depending on the number of cylinders, four or six pipes are combined into an intake manifold. They converge in a central intake point.

There are some additional components in the intake manifold:

| – Heating element: This is used to preheat the intake air. – Swirl dampers with control: They swirl the air additionally. – Intake manifold gaskets – Connector for the EGR valve |

Intake manifold – Discount24h free shippingto the shop ⇒ |

Excursus: Nitrogen oxides from exhaust gases

Pollutants are produced when fuels such as petrol, diesel or natural gas are burned. But it is not carbon monoxide, carbon dioxide or soot particles that cause the biggest problem. Pollutants are produced when fuels such as petrol, diesel or natural gas are burned. But it is not carbon monoxide, carbon dioxide or soot particles that cause the biggest problem.The main culprit is created incidentally during combustion in the engine: the so-called nitrogen oxides are identified as the main cause of air pollution. However, nitrogen oxides are always produced when something is burnt with atmospheric oxygen. Air consists of only about 20% oxygen. Most of the air we breathe is actually nitrogen. A whopping 70% of the ambient air is nitrogen. Unfortunately, this gas, which is in itself very inert and non-flammable, combines under the extreme conditions in the combustion chambers of an engine to form various molecules: NO, NO2, NO3 etc. are the so-called “nitrogen oxides”, which are combined to form the NOx group. But because nitrogen is so inert, it quickly loses the attached oxygen atoms. And then they become the so-called “free radicals“, which oxidise everything they come into contact with. If you breathe them in, they damage the lung tissue, which in the worst case can lead to cancer. To reduce the concentration of nitrogen oxides, the EGR valve is used on an intake manifold. |

Problem with EGR valve

An EGR valve is used to return the already burnt exhaust gas to the combustion chamber. To do this, exhaust gas is fed through the intake manifold. The engine sucks in exhaust gas that has already been burnt and burns it again. This does not affect the engine’s performance much. However, this trick lowers the temperature of the combustion process. The lower the temperature in the combustion chamber, the less nitrogen oxides are formed.

An EGR valve is used to return the already burnt exhaust gas to the combustion chamber. To do this, exhaust gas is fed through the intake manifold. The engine sucks in exhaust gas that has already been burnt and burns it again. This does not affect the engine’s performance much. However, this trick lowers the temperature of the combustion process. The lower the temperature in the combustion chamber, the less nitrogen oxides are formed.

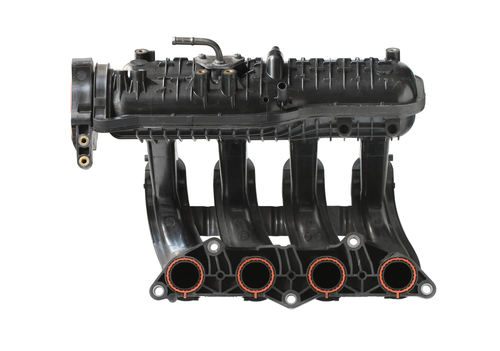

However, there is a catch. The soot particles from the exhaust not only settle in the EGR valve. They also gradually clog the entire intake manifold. This can lead to a total blockage of the line. The car then actually gets no more air and can practically no longer be operatable.

Intake manifold repair

Total contamination due to deposits from the exhaust gas is the most common cause of a defective intake manifold. Until recently, the entire component was simply replaced – but always at huge cost.

In the meantime, however, there are many service providers who offer to clean the intake manifold.

| There are several approaches to this: Some service providers burn out the intake manifold with pure oxygen or compressed air. Others rely on chemical solutions in which the solid carbon is dissolved from the soot in acid. These service providers usually offer an immediate “old for reconditioned” exchange or the restoration of your own intake manifold. A new intake manifold costs up from about 150 to well over 1000 pounds. Reconditioning usually costs less than 1/4 of the new price of an intake manifold. |

The trick, however, is in the detail: Removing an intake manifold required some experience, sure instinct, and suitable tools. If the intake manifold is damaged during removal, it can only be replaced with a new part.

Cleaning the intake manifold always includes maintenance of the EGR valve.

Issue with swirl dampers

Swirl dampers are installed on many intake manifolds. These are small flaps made of heat-resistant plastic. Not only do they open and close the intake ducts of the intake manifold. They provide swirl, which is supposed to improve combustion in the engine, above all. The problem with swirl dampers, however, is that they tend to break off and then fall into the engine compartment.

If you are lucky enough, the piston will crush the plastic flap and blow it out with the exhaust gas. But even then, pieces of it get caught in the catalytic converter at the latest. If you are unlucky, the broken swirl damper will cause serious engine damage even before that.

![]() Our tip is therefore: Find out whether a replacement set is available for your vehicle.

Our tip is therefore: Find out whether a replacement set is available for your vehicle.

These are available for many BMW engines, for example. In the set, the movable flaps are replaced with rigid covers. The effect is minimally worse, but you get maximum operational reliability. The covers cannot break off and fall into the engine compartment. You are thus reliably protected from unpleasant surprises.

Foto: Lena Pan, CyrilLutz, aopsan, Byjeng, Chirachai Phitayachamrat, KUNANEK SUPAKOSOL, Winai Tepsuttinun, Stason4ik / shutterstock.com