Injection nozzles or injectors serve to permanently deliver the right amount of fuel into the combustion chamber of diesel engines. These small but highly stressed components ensure that the engine runs correctly thousands of times a minute. Despite being made of high-quality materials, these components are subject to wear. Here you can read how to recognise defective fuel injection nozzles and how to deal with the damage.

Direct injection engine needs pressure

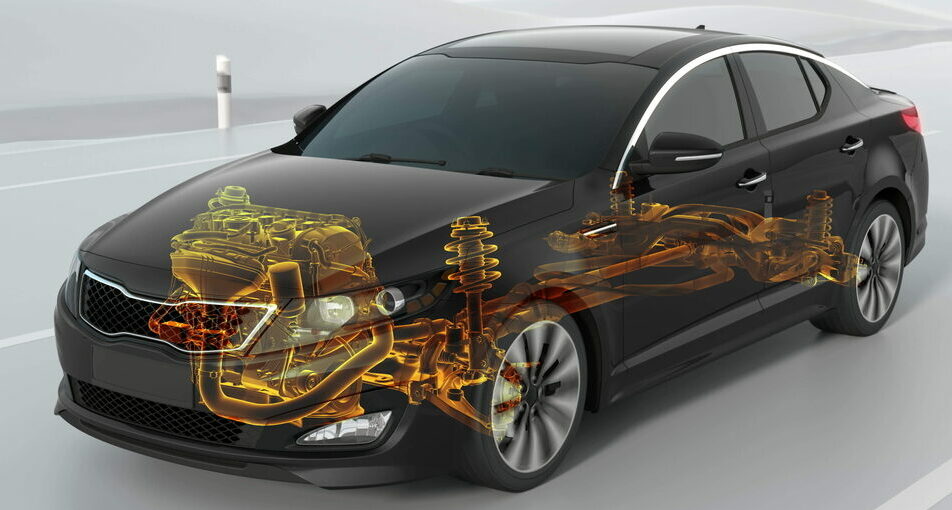

Diesel engines are so-called “self-igniters”. This means that they do not need external ignition in the form of a spark plug to burn the fuel. The compression pressure generated by the piston moving upwards is enough to lead to the desired explosion of the diesel-air mixture.

However, it is important that the correct amount of diesel is injected into the combustion chamber at exactly the right moment in the optimally atomised form. Be the drops too large, the diesel will not burn completely. Be they too small, the engine gets too hot or does not run properly.

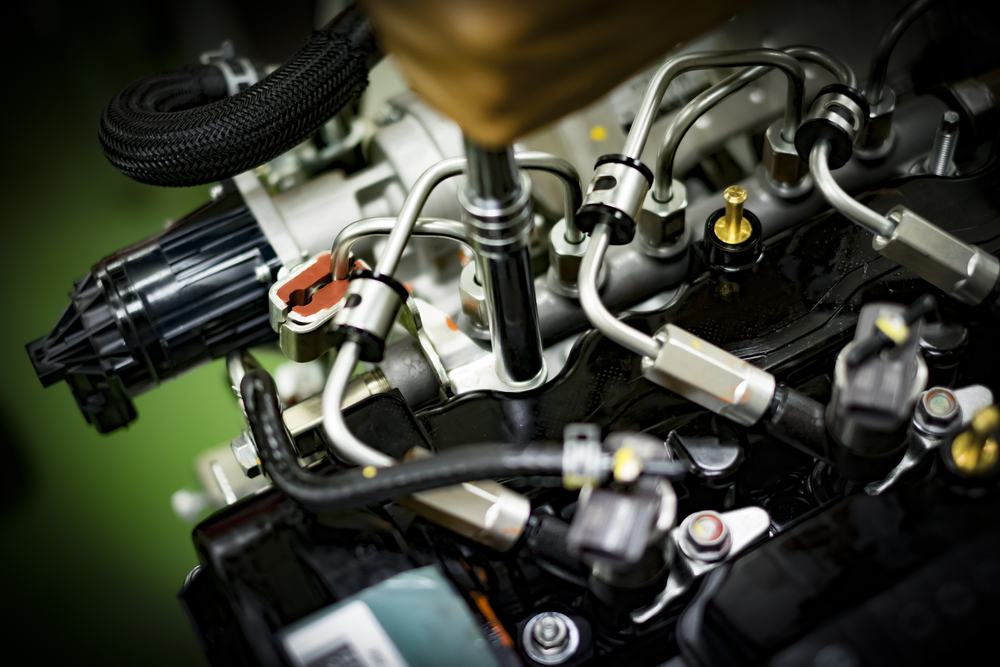

In order to create this reliable condition, the injection nozzles (usually built as a pump-nozzle unit) deliver the fuel into the combustion chamber at high pressure. The average pressure is 300-400 bar. Volvo, however, has a model that operates at pressure of 1400 bar.

In addition to diesel engines, there are also petrol engines that operate on direct injection. They use fuel injectors as well.

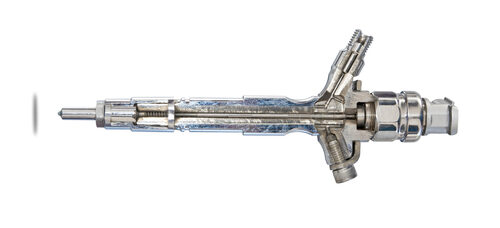

Structure and position of a fuel injector

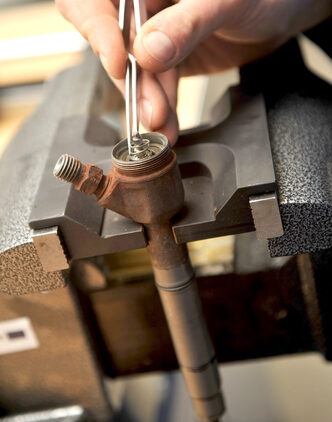

An injection nozzle consists of a nozzle part and a pump part. The nozzle protrudes into the combustion chamber. It consists of a hollow pin with a 0.2 mm wide bore.

The pump which injects the fuel into the combustion chamber under the required pressure is installed at the rear part of the same component. Thus, each injector has its own pump. It always consists of a hydraulic piston that is reset by a spring. The injectors are located at the top of the cylinder head, like the spark plugs on a gasoline-powered car.

Defects in a fuel injector

An injection nozzle is a mechanical component that is subject to high stress. It undergoes extremely strong forces on and in it. It is also subject to high thermal stress. The main cause of defects is coking on or inside the nozzle.

- Coking is the residue of incompletely burnt fuel.

This forms a plaque, which further worsens the combustion, making the plaque bigger and bigger.

Defects in the fuel injector have the following symptoms:

|

– Poor engine start – High fuel consumption – Black smoke from the exhaust under load – Jerky engine |

A defect in an injector is by no means just expensive and annoying. If not repaired as soon as possible, it may lead to serious engine damage. Problems with the injectors should therefore not be delayed but handled immediately.

Injection nozzles & injectorssuper inexpensive up from £5,29Buy online ! ⇒ |

Diagnostics of fuel injectors

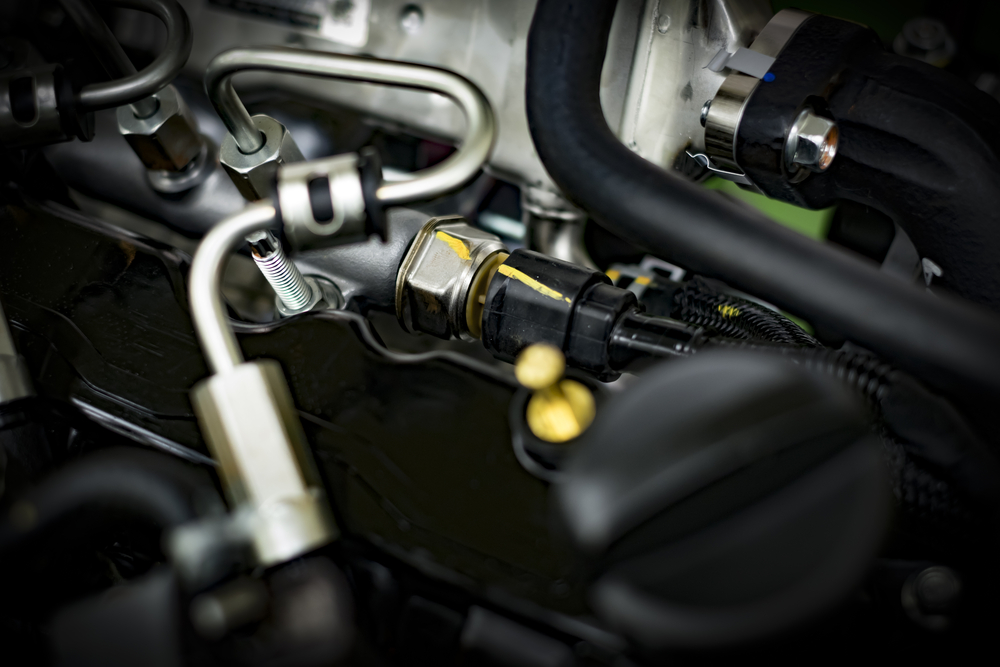

There is a simple and very safe way to test the function of the fuel injectors on the engine. Basically, all you need are rubber hoses and as many equally sized jars as there are cylinders in the engine. The hoses are connected to the drain line of the injectors and attached to one jar each. Now start the engine and let it run for 1-3 minutes. If the injectors are intact, the same amount of fuel will come out into each jar.

Defective injectors are detected by the fact that they release considerably more or considerably less fuel through the drain line.

For such a diagnostic, the market offers a test kit for about 80 pounds. It is highly recommended, as it is designed precisely for this purpose.

How to deal with defects on injectors

Before you read: injectors are very expensive. For a single injector, you should consider 220 – 350 pounds. Since injectors should always be replaced as a complete set, you should expect to pay between 900 and 1500 pounds for spare parts.

The good news, however, is that there are now a large number of specialist companies that can refurbish injectors. In this process, the injector is cleaned of all adhesions and all wearing parts, such as seals or clips, are replaced.

The injector is then tested and returned to the customer as a quasi-new part. The use of refurbished parts also has a great advantage: the engine’s control unit does not have to be readjusted when the refurbished injectors are installed. For this purpose, however, it is important that each injector is returned to the exact position in which it was previously installed.

In theory, removing injectors is quite simple. They are not screwed in like spark plugs, but are usually “only” plugged in. They are held in place by clamps attached above them. In practice, however, things look quite different. In order to get to the injectors, a lot of things have to be dismounted.

If they are exposed and the retaining clips are loosened, the car enthusiast is often in for a nasty surprise: the injector sits unshakeably in the engine and does not allow to be loosened even with the greatest effort. For this purpose, well-known manufacturers have developed special solvents that trigger the caking responsible for the tight fit of the injector.

However, even with the use of the solvent, the removal of an injector can become an enormous feat of strength. The important thing here is never to lose patience and not to cause further damage to the engine.

Always work on all injectors!

Since all injectors are stressed almost equally, they wear out also almost the same way.

Since all injectors are stressed almost equally, they wear out also almost the same way.

Even if only one or two injectors are found to be defective during the test, the failure of the other injectors is only a matter of time.

The most economical way is therefore to have all injectors overhauled by a service provider. A new injector should be purchased as anew only when the specialist reports that it can no longer be refurbished.

This way, you save high costs and have a perfectly functioning engine again.

Reasonable extras

With the injectors removed, the car is practically immobilised. It is therefore a good opportunity to move on with further repairs. With diesel engines, it is advisable to have the EGR valve and the intake manifold cleaned as well. These also coke up over time.

The particle filter in the exhaust could also be removed and cleaned by a specialist. Finally, when the overhauled injectors are installed, all paper filters such as pollen, cabin or engine air filters can also be replaced. The diesel filter is also changed so that the overhauled injectors only get guaranteed clean fuel.  Finally, an oil change for smooth and clean engine running is the last measure to start the next thirty thousand kilometres with peace of mind.

Finally, an oil change for smooth and clean engine running is the last measure to start the next thirty thousand kilometres with peace of mind.

Foto: Romaset, CHAINFOTO24, Stason4ik, Srdjan Jovic, AlxAustralia, Guzhva Vera, Tomasz Romski, MR.TEERASAK KHEMNGERN, u3d / shutterstock.com

(28 votes, average: 4.71 out of 5)

(28 votes, average: 4.71 out of 5)