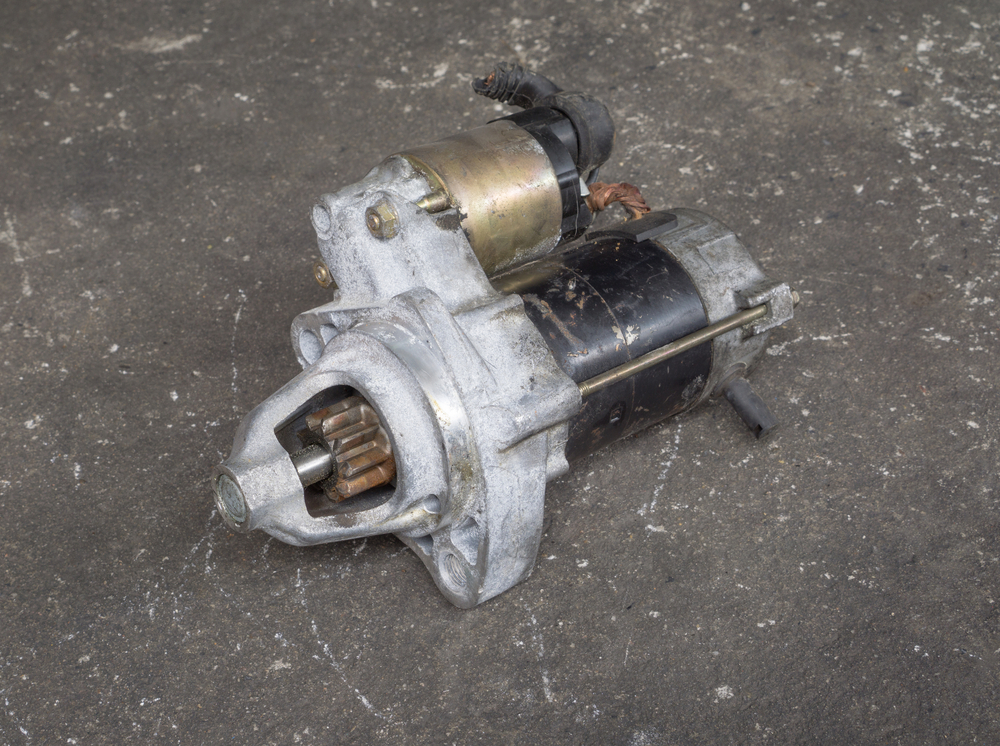

The starter motor is a central element in every motorised vehicle. Neither a petrol nor a diesel engine can start by itself in a standing position. The fuel in the engine is supplied with oxygen by suction and subsequent compression prior to ignition, the starter motor initiating this process. A defective starter causes serious problems.

This is how a starter works

The starter motor enables the engine to run. A combustion engine needs assistance to overcome mass inertia as well as friction and compression resistance. This is the starter’s task.

The starter motor enables the engine to run. A combustion engine needs assistance to overcome mass inertia as well as friction and compression resistance. This is the starter’s task.

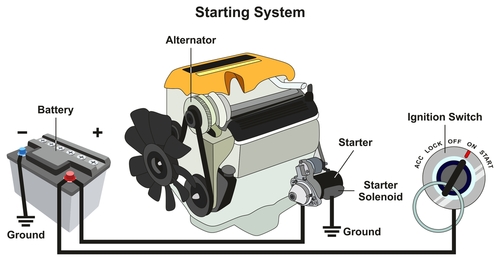

Essentially, it is an electric motor directly driven by the battery. The starter motor in its turn drives a flywheel. During the starting procedure, the starter motor with its pinion sets a flywheel in motion at ca. 300 rpm, which is sufficient to start the engine and allow the following process to function automatically. As soon as the ignition is completed and the engine is running independently, the starter is switched off.

A starter is one of the most reliable components in a car and doesn’t need any maintenance. Nevertheless, defects can occur.

Tell-tale signs of a defective starter

Several symptoms suggest a defective starter. It is important to heed these symptoms in order to react timely. If the starter is inoperative, the car can no longer be started.

Several symptoms suggest a defective starter. It is important to heed these symptoms in order to react timely. If the starter is inoperative, the car can no longer be started.

Starter with 30% discountfrom £66,39 by premium manufacturersBuy now ⇒ |

The most important symptoms are the three following:

|

– a loud squeak after starting the engine – a flywheel pinion running slower than usual – starting fails despite charged battery |

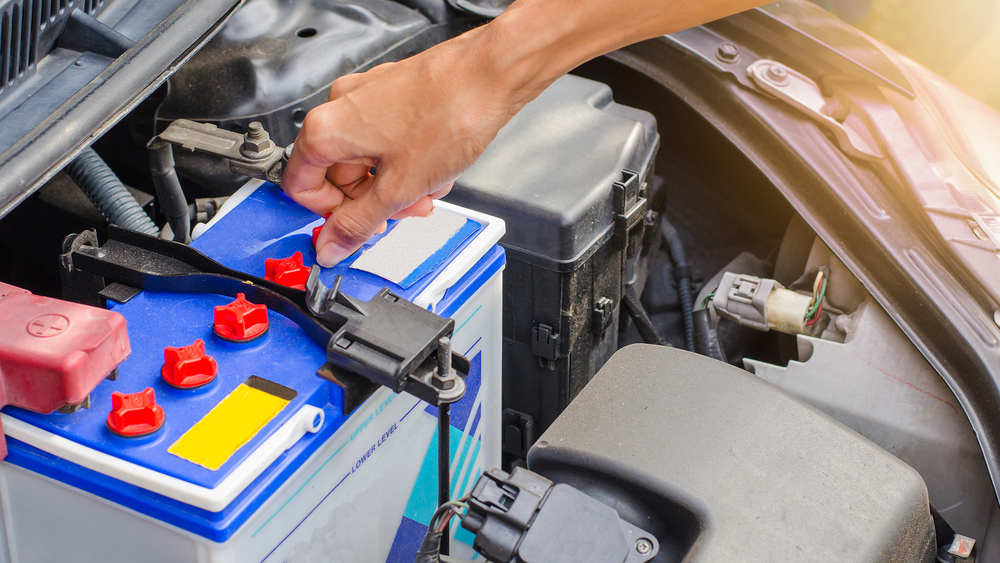

- The first thing to check in case of starting problems, is the battery which can be the cause of a starting failure as well. Replacing the battery is easier and cheaper and therefore it is important not to skip this step.

- If the car cannot be started despite a new battery, the cause of the problems is in all likelihood the starter motor. It now has to be replaced as soon as possible in order to use the car. Before taking this step, be sure to exclude other fault sources first.

Other fault sources besides the starter motor

- In addition to the battery, the power supply plays an important role. A single defective cable can cripple the starter and cause problems. Test all accessory cables to exclude possible failures or a cable rupture.

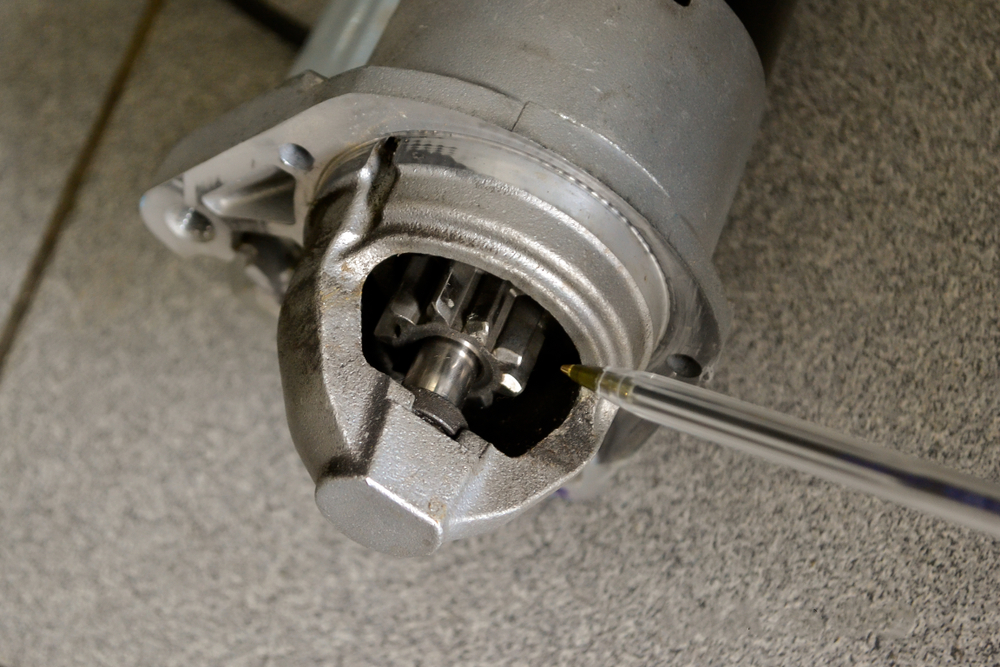

- The flywheel pinion can wear out too. This component enables the starter to generate the necessary rotation. When the cogwheels no longer grip, the starter runs idle without igniting the engine. If this is the case, only the flywheel pinion needs replacement instead of the entire starter motor. This is considerably cheaper although it implies more work. At least the costs for a new starter are avoided.

Replacing a starter: garage or DIY?

- Principally, in case of engine maintenance it is recommended to go to a garage.

- Yet for starter motor replacement this greatly depends on the car model and the manufacturer.

Especially in modern cars, the starter motor is difficult to find and to reach. Finding the way under the many protective caps and lids is no easy job for a DIY’er.

Especially in modern cars, the starter motor is difficult to find and to reach. Finding the way under the many protective caps and lids is no easy job for a DIY’er.

In older cars, the replacement is generally simple. Here, the starter is replaced in the upper part of the engine compartment.

In older cars, the replacement is generally simple. Here, the starter is replaced in the upper part of the engine compartment.

If you want to be very thorough, locate the starter’s position first to decide whether you can do it yourself.

Following tools are needed

For starter motor replacement several tools are required. They can vary according to car type but with this list you are on the safe side. You need:

|

– a spanner set – a screwdriver set – allen key set – a multimeter |

These tools enable you to perform the replacement.

Step-by-step the starter motor replacement

To replace the starter, follow these steps:

| – localise the starter in the engine compartment. – if necessary, jack up the car to reach the starter. – disconnect the negative battery pole and put it aside. – record precisely which cable is connected where on the starter. – unscrew the device’s mounting screws. Start with the least accessible screw. – unplug the separate cables. Again, make a note of the colours and connection. – take out the starter. In a few car models, removal of other components such as the drive shaft or exhaust components is required. – compare the disassembled starter with the spare part. – check the flywheel & cogs – install the new starter. – fix the screws. – connect the cables with the starter. – connect the battery. – test the new starter. |

Be sure to avoid the following errors

Assembly and replacement of a starter motor looks uncomplicated. Yet, don’t think too lightly of it.

It is important to avoid certain errors such as omitting to disconnect the battery.

Swapping the separate cables is another often occurring error, which could damage the new starter motor.

Therefore be sure to double-check which cable belongs to which connection.

Mind all these steps and the starter motor replacement should not pose any problem. Depending on car type and model you can perform this maintenance in 30 minutes or two hours at most.

Be certain to work steadily and cautiously. Then, it should be easy for DIY’ers as well.

Foto: udaix, Aleksandr Kondratov, Supit Choosavang, Ivan Krawchuk, Chonlawut, PAKULA PIOTR, Sergey Ryzhov, Patcharapa, Eblis, Andriy Smalchuk, kurhan, Alraun / shutterstock.com

(10 votes, average: 3.60 out of 5)

(10 votes, average: 3.60 out of 5)