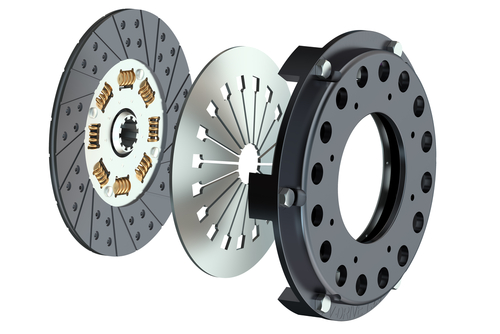

The clutch is not a separate part, but a complex system responsible for the transmission of power between the engine and the gearbox, enabling gear shifting. Its life span strongly depends on the car and the individual driving style. Heeding our advice, you can exponentially extend the life span of your clutch. Furthermore we’ll show you how to vent the clutch and how to service a new clutch after replacement.

Is it time for a new clutch?

Is it time for a new clutch?

Almost all symptoms indicating a defective clutch occur gradually and are only noticed by the driver at a later stage. Everybody knows the nasty grinding noise when changing gear, indicating the connection not being fully separated. If this occurs repeatedly, even when fully applying the clutch pedal, the wear is often at an advanced stage and replacement is in most cases inevitable. If it is merely play in the clutch pedal, causing the clutch to react with delay and you need to apply more force than usual to disengage, this is an indication of air in the main cylinder. In this case you can vent this yourself with a bit of technical know-how. If you are no longer able to accelerate because the engine is being stalled despite giving sufficient throttle, there is likely a system defect.

Almost all symptoms indicating a defective clutch occur gradually and are only noticed by the driver at a later stage. Everybody knows the nasty grinding noise when changing gear, indicating the connection not being fully separated. If this occurs repeatedly, even when fully applying the clutch pedal, the wear is often at an advanced stage and replacement is in most cases inevitable. If it is merely play in the clutch pedal, causing the clutch to react with delay and you need to apply more force than usual to disengage, this is an indication of air in the main cylinder. In this case you can vent this yourself with a bit of technical know-how. If you are no longer able to accelerate because the engine is being stalled despite giving sufficient throttle, there is likely a system defect.

Clutch kit ⇒ at the offer priceinexpensively up from £ 35,35Go to shop ⇒ |

How to test your car clutch performance

You can check with a simple test if the clutch power is still sufficient. Place your car on an open area, as flat and even as possible, switch off the engine and apply the hand brake. Disengage the clutch and start the engine at idling speed. Change to higher gears. In an ideal case the engine will stall in the highest gear (please switch carefully). If nothing happens, the wear is already advanced. Ultimately in third gear, the clutch power should interfere with the engine running. If this does not happen, the clutch is lost and you need a new one.

You can check with a simple test if the clutch power is still sufficient. Place your car on an open area, as flat and even as possible, switch off the engine and apply the hand brake. Disengage the clutch and start the engine at idling speed. Change to higher gears. In an ideal case the engine will stall in the highest gear (please switch carefully). If nothing happens, the wear is already advanced. Ultimately in third gear, the clutch power should interfere with the engine running. If this does not happen, the clutch is lost and you need a new one.

Venting the clutch and adjusting the free play from the pedal

Venting the clutch and adjusting the free play from the pedal

If the clutch power is still sufficient although you feel play in the pedal, requiring additional force to disengage, there is likely to be air in the system. The hydraulic clutches installed in most modern cars can relatively easy be vented. As an absolute beginner you will need supervision, though not much can go wrong apart from more air getting into the system. If you do not succeed in venting the clutch, you can visit a garage which has a special device functioning with a parallel system, removing 100 % of the air.

![]() You need the following equipment:

You need the following equipment:

– torque spanner with fitting head

– brake fluid (see car manual)

– screwdriver

– possibly car jack

– a piece of hose (ideally transparent) and a hose clamp

– container

Before you start: find the brake fluid reservoir first and fill it with proper brake fluid until the top mark. This ensures the immediate replacement of the air in the cycle. Before you start: find the brake fluid reservoir first and fill it with proper brake fluid until the top mark. This ensures the immediate replacement of the air in the cycle. |

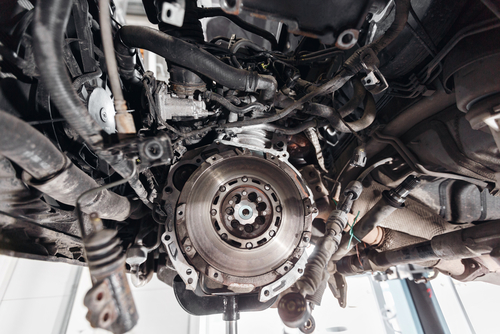

Step 1: Ask your helper to sit in the car. Lie down under the car or jack up the passenger’s side with the jack. Follow the gearbox as it comes from the direction of the engine. Behind it you find the clutch slave cylinder. If you cannot locate it, observe the direction of brake fluid hose. It should end in the master cylinder. Step 1: Ask your helper to sit in the car. Lie down under the car or jack up the passenger’s side with the jack. Follow the gearbox as it comes from the direction of the engine. Behind it you find the clutch slave cylinder. If you cannot locate it, observe the direction of brake fluid hose. It should end in the master cylinder. |

Step 2: Remove the dust cap from the venting screw by careful levering it with the screwdriver. Alternatively remove the small clamp by inserting the screwdriver between it. Step 2: Remove the dust cap from the venting screw by careful levering it with the screwdriver. Alternatively remove the small clamp by inserting the screwdriver between it. |

Step 3: Place the hose and the clamp on the now visible nipple of the venting valve. Fill the reservoir with braking fluid and hang the other end of the hose in it. Step 3: Place the hose and the clamp on the now visible nipple of the venting valve. Fill the reservoir with braking fluid and hang the other end of the hose in it. |

| Step 4: Ask your helper to forcefully step on the clutch pedal fully pressing it down and repeat this procedure at least five times. In the end the pedal must be kept continuously pressed. |

Step 5: Open the valve with a box spanner and observe the hose and the reservoir. As soon as no bubbles rise in the brake fluid and it runs through the hose, close the valve. Step 5: Open the valve with a box spanner and observe the hose and the reservoir. As soon as no bubbles rise in the brake fluid and it runs through the hose, close the valve. |

| Step 6: Repeat this procedure until all air has been vented from the system. |

Step 7: Shut the valve provisionally, release the clutch and check the level in the brake fluid reservoir. If it is less, fill it up to the top mark. Step 7: Shut the valve provisionally, release the clutch and check the level in the brake fluid reservoir. If it is less, fill it up to the top mark. |

| Step 8: Close the valve with the torque spanner until ca. 4 Nm torque. |

Step 9: Remove the hose and put the dust cap back, if necessary with its clamp. Step 9: Remove the hose and put the dust cap back, if necessary with its clamp. |

| Step 10: Change gear a couple of time. Observe the necessary applied force on the pedal. Ultimately perform the previously described clutch test. If everything is alright, the venting was successful. |

Avoiding damages: this is how you spare your clutch

Avoiding damages: this is how you spare your clutch

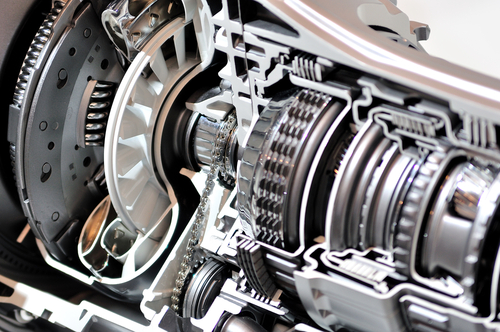

Basically, the clutch is created to keep wear at its minimum when properly used. This particularly applies to cars with an automatic transmission. As everything functions automatically without any interference from the driver, these transmissions have a life span up to 300.000 km and seldom need replacement even in case of prolonged use of the car. The situation is totally different for manual transmissions. Their life span lies between 20.000 and 200.000 km, which is a clear indication of the extent in which you can influence the performance by your driving style.

If you want to spare your clutch, you need to observe the following points:

| – Press fully: Even if it is difficult and in some cars cause muscle pains, at all times you need to try to fully apply the clutch. The reason for this lies in its construction: only in this way the optimal point with respect to material strain is reached, which is essential for switching gear. This applies to the gear lever as well. If you nervously start pulling at the lever before the end of disengagement in order to shift to the following gear, you will not enjoy your gearbox and clutch for long. |

| – Take your foot from the pedal: What is essential in racing, should not be ignored in normal road traffic. Keeping your foot on the pedal for a long time after changing gear causes mechanical stress and shortens its life span. Therefore keep it pressed as short as possible and take your foot from the clutch pedal immediately. Also when waiting at the traffic light there is no need for keeping the foot on the pedal, changing into neutral and applying the hand brake. Of course: in case of short stops and fast traffic this is not really necessary. Nevertheless at large intersections it may last at least 30 seconds. |

| – When parking, no strain on the gearbox: A tip not only sparing the clutch, but also the gearbox. When parking the car, switching to neutral and applying the hand brake takes pressure from the gearbox and clutch, generally responsible for suppressing the engine. No panic: an adequately functioning hand brake keeps the car in place even on slopes. Only if it is too badly worn this can lead to problems. |

| – Avoid changing gear: Changing into higher gear at the traffic light although it is obvious that you will need to brake again soon? If you adhere to this driving style, you can kiss your clutch goodbye very soon. Avoid changing gear should be the motto. Driving in an anticipating manner is the best strategy. Particularly beginners experience difficulties with this. Gaining experience, assessing the situation will work better all the time. Ultimately you will be able to reduce the gear shifting to a minimum. |

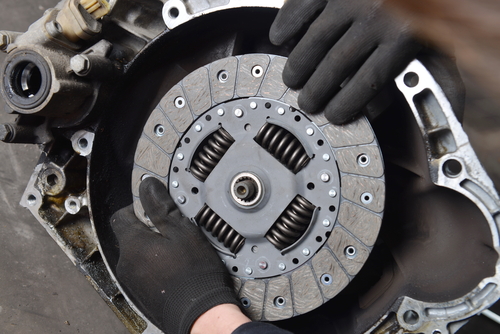

Breaking in the clutch after replacement

Breaking in the clutch after replacement

– this is how you do it

After clutch replacement, the garage will most certainly tell you to “take it easy” in the time coming. There are several reasons for this. To begin with, the mechanical parts require some time to reach their optimal harmony with respect to possible tolerances. Furthermore, lubricating agents such as grease and oil need some time to adequately spread through the entire system. Your clutch is broken in after ca. 1000 km. While doing do, you need to observe the following:

After clutch replacement, the garage will most certainly tell you to “take it easy” in the time coming. There are several reasons for this. To begin with, the mechanical parts require some time to reach their optimal harmony with respect to possible tolerances. Furthermore, lubricating agents such as grease and oil need some time to adequately spread through the entire system. Your clutch is broken in after ca. 1000 km. While doing do, you need to observe the following:

| – Driving with a possible low rpm. Also on the motorway change to higher gear and switch back as late as possible. Not exceeding 4000 rpm is recommended. |

| – On occasion of starting on a slope on no account allow the clutch to slip, but work with the hand brake. In emergency situations, the rpm limit can for a short while be exceeded, because the strain on the clutch is still always lower than with the clutch-slip method. |

| – During the first 500 kilometres, towing trailers, caravans or carrying bicycle racks should be avoided. A clutch occasionally making noise or almost stalling the engine following a clutch replacement is normal. If this still occurs after driving 1000 km, you need to check into a garage as soon as possible, as an installation error might have occurred. Possibly, the friction surface of the clutch disc is responsible for this. In this case improvement of the friction surface is possible by driving up the hill under supervision of the garage. |

Foto: Thanapun, Iakov Filimonov, AlexLMX, Visionsi, loraks, malkovkosta, Tom Wang / shutterstock.com