Laying a wiring harness in the car is more than just connecting a car radio or subwoofer. The wiring harness is practically the nerve connection in the car, linking all the sensors, actuators, and consumers together. If mistakes are made when repairing or rewiring a wiring harness, even the car may end up in flames. Therefore: Always know what you are doing and always make sure you work cleanly.

When should a wiring harness be rewired?

Replacing a complete wiring harness in a car is actually quite a rare repair. Most of the time, this measure becomes necessary if you have caught a cable fire or an unknown short circuit simply cannot be found.

Also, the wiring harness is usually re-routed during a full restoration. The existing wiring of a classic car is usually already so brittle and oxidised that only a completely new harness can provide the necessary operational safety.

Biting, chafing, tearing – the enemies of cabling

A wiring harness consists of a power line and insulation. Electricity always flows in circles, that’s why it’s called a “circuit“. A line must always run from the power source to the consumer – and back again.

For cost reasons, however, not every line is laid twice. The energy sources, i.e. the alternator and the battery, are connected to the car body on one side.

High quality car batteryavailable up from £53,23Order online ⇒ |

The metal sheet of the car is thus practically used as a return line – this is the famous “earth connection”. If a power line loses the insulation due to a marten bite, a crack or a chafe, the current short-circuits through the bodywork.

The metal sheet of the car is thus practically used as a return line – this is the famous “earth connection”. If a power line loses the insulation due to a marten bite, a crack or a chafe, the current short-circuits through the bodywork.

The consumer is no longer supplied with power and fails. At the same time, the cable heats up and expands at the damaged spot. The damage therefore continues and can, in the worst case, lead to a fire.

So test who binds himself eternally…

Replacing a wiring harness is a very lengthy and costly repair. It is true that the individual cable is very inexpensive. However, a complete, pre-assembled harness can be very expensive.

You should keep away from buying second-hand: The time it takes to tear an existing harness out of an old vehicle is disproportionate to the benefit. And then you have a used part of which you don’t know how it has already been used.

Apart from that: Even wiring harnesses that have already been dismantled still have their price: You have to reckon with 200 – 1100 pounds for these replacement parts.

Better idea: repair kits

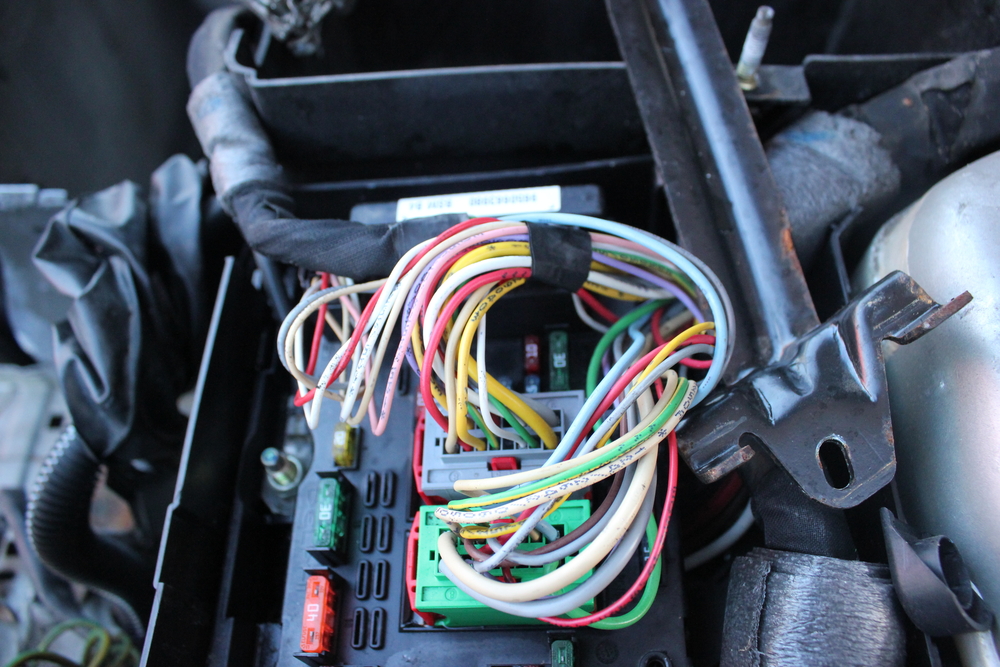

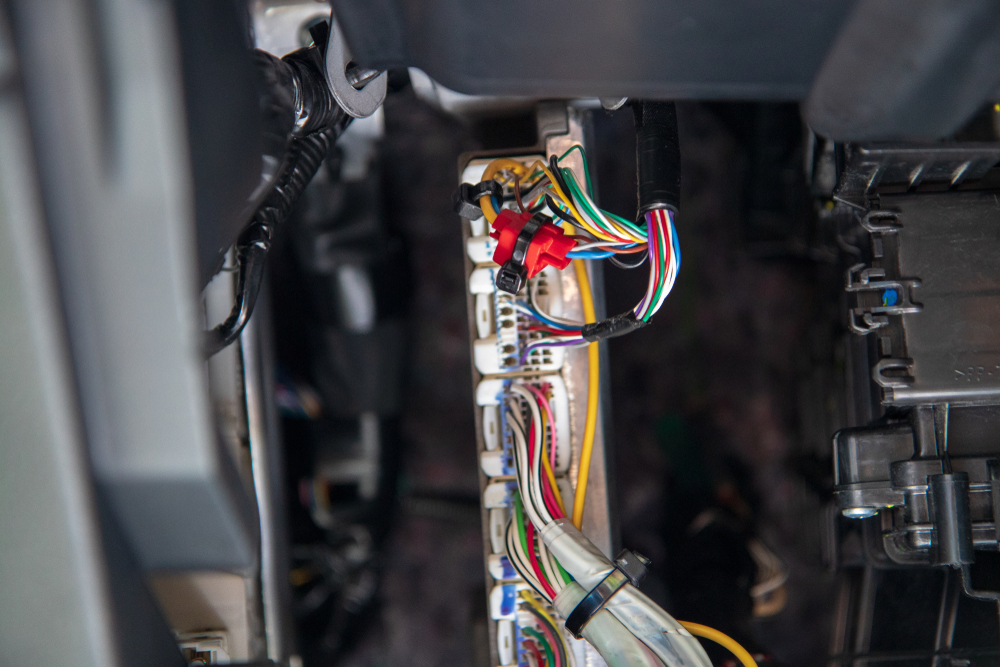

Fortunately, wiring harnesses of today are mostly modular. This means that there is only one main harness that is detachably connected to various secondary harnesses. Typical secondary harnesses are, for example, the doors, the tailgate, or the front headlight battery.

This makes sense, since there are numerous consumers in every corner of the car today, all of which want to be supplied. In a door, for example, you will find the power supply for the window lifters, the associated switches, the power-operated and heated rear-view mirror, which is also equipped with an indicator. That adds up pretty quickly.

Only work with the best quality

When working on the wiring harness, the following applies: Every pound more invested in equipment, tools and spare parts pays off in time savings and better results. A good starter set for a successful wiring harness repair consists of:

|

– Multimeter – Wire stripper – Exchange harness made of solid copper wire – High-quality connecting plugs – If necessary, high-quality insulating tape. |

The multimeter is the best thing to save money. The models available today start at 8 pounds and offer usable quality.

Inform, inform, inform

The tricky thing about electric current is that you can’t see what it’s doing from the outside. With the low voltage in a car, it is especially difficult to figure out the respective course of the currents.

Therefore, before repairing and replacing components in the wiring harness, the car’s wiring diagram should be examined in detail. Without information and precise knowledge of which cable is responsible for which consumer, one should not even begin.

Tinkering with patched wires should no longer be done today. The control units react sensitively to fluctuations in the resistances. They quickly misinterpret the signals from sensors if the wires are repaired unprofessionally.

Control units • Car partsinexpensively up from £27,66go to shop ⇒ |

A wiring harness is repaired by professionally replacing the sub-module or replacing a damaged cable with an identical or higher quality one.

Always check connectors

The individual modules of a cable harness are usually connected to each other by multi-plugs. Loose banana plugs or even lustre terminals are no longer used at the factory. If you find such provisional connectors on your car, you can be sure that a tinkerer has been at work here.

Here the motto is: Be careful. Anyone who repairs a car wiring harness with a lustre terminal is also doing other things. It is better to take a close look at the component and, if necessary, replace the wiring harness.

Plugs have the unpleasant property of corroding. Since the contact surfaces are made of aluminium, a corroded spot is not so easy to find. The combination of moisture and electrical voltage causes even rust-free aluminium to weather over time.

Unlike red iron rust, aluminium oxidises to a white powder. This powder layer cakes onto the corroded area and gradually isolates it. Therefore, when replacing sub-modules from the wiring harness, one should always check the connectors for corrosion and clean them thoroughly.

Converting plugs

You have probably noticed that a multi-plug has many more slots than connections are made with. The reason for this is that these plugs can be converted.

Our recommendation, however, is not to reuse plug tongues or flat plug sleeves that have been pulled out once. These components can be bought for about 1 pound in packs of 100 pcs. You should not break your fingers on a used part, but always use new connections.

Rebuilding a multi-plug is fiddly enough as it is. But with a little practice you can do it. A reliable and high-quality pair of needle-nose pliers is helpful.

Work on the main culprit first

Many problems with a car’s electrical wiring have a common cause: a corroded ground wire. This is a particularly simple repair and there is not much you can do wrong.

The ground cable leads from the battery to the body. It is a thick, black cable or an open wire mesh. Severe corrosion can occur at the battery and body contact points until the cable no longer reliably conducts electricity.

If the earth cable is not brittle, it is enough to clean grind the contact points on the cable and the bodywork, and then reconnect them. A dab of battery grease prevents renewed corrosion. In this way, a “spinning electrical system” can be repaired in a few easy steps.

Foto: Golubovy, Cosmin Sava, SchottiU, Ankie E, Aleksandr Kondratov, Golf_Waranon, Chubarov Mikhail, AMNAT DPP, Imagine Photographer, Serhii Bobyk / shutterstock.com