Shock absorbers wear slowly. For a long time you do not notice the driving quality gradually deteriorating. Sooner or later the moment arrives when you can no longer ignore the spongy steering: a clear signal of worn shock absorbers. Not only is this uncomfortable, but also dangerous. Read here everything you need to know about the replacement of shock absorbers.

Construction and function of a shock absorber

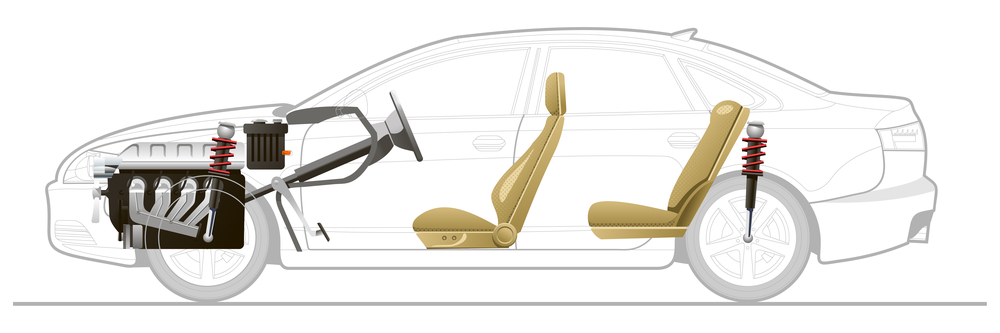

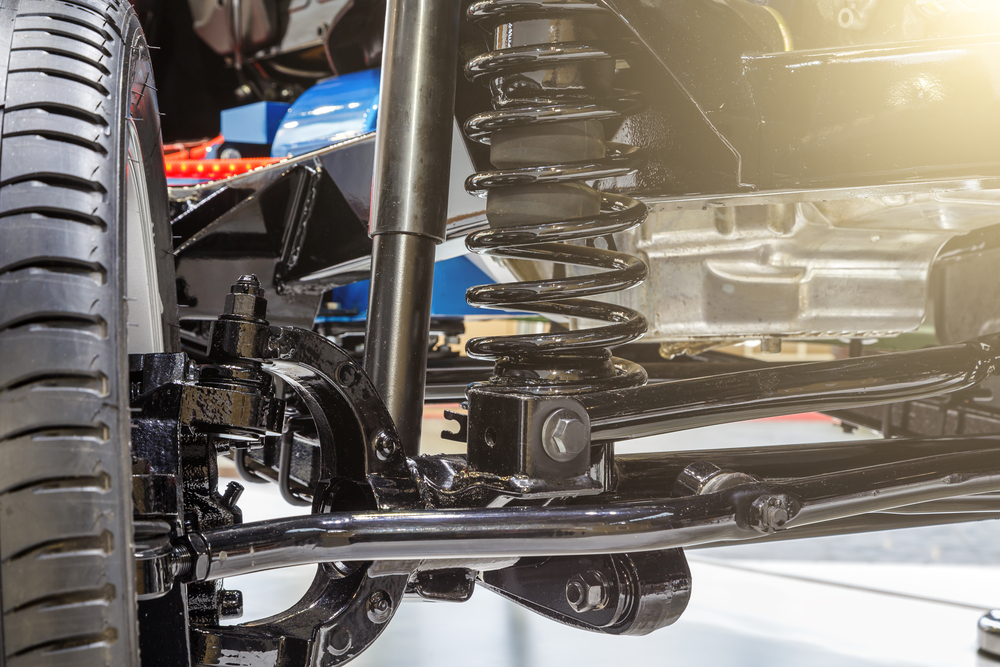

A shock absorber absorbs the wheels’ movements when driving over bumps, transmitting them to the bodywork in a damped and delayed manner. This makes driving more comfortable as well as safer. The car maintains its track and does not swerve during driving.

A shock absorber absorbs the wheels’ movements when driving over bumps, transmitting them to the bodywork in a damped and delayed manner. This makes driving more comfortable as well as safer. The car maintains its track and does not swerve during driving.

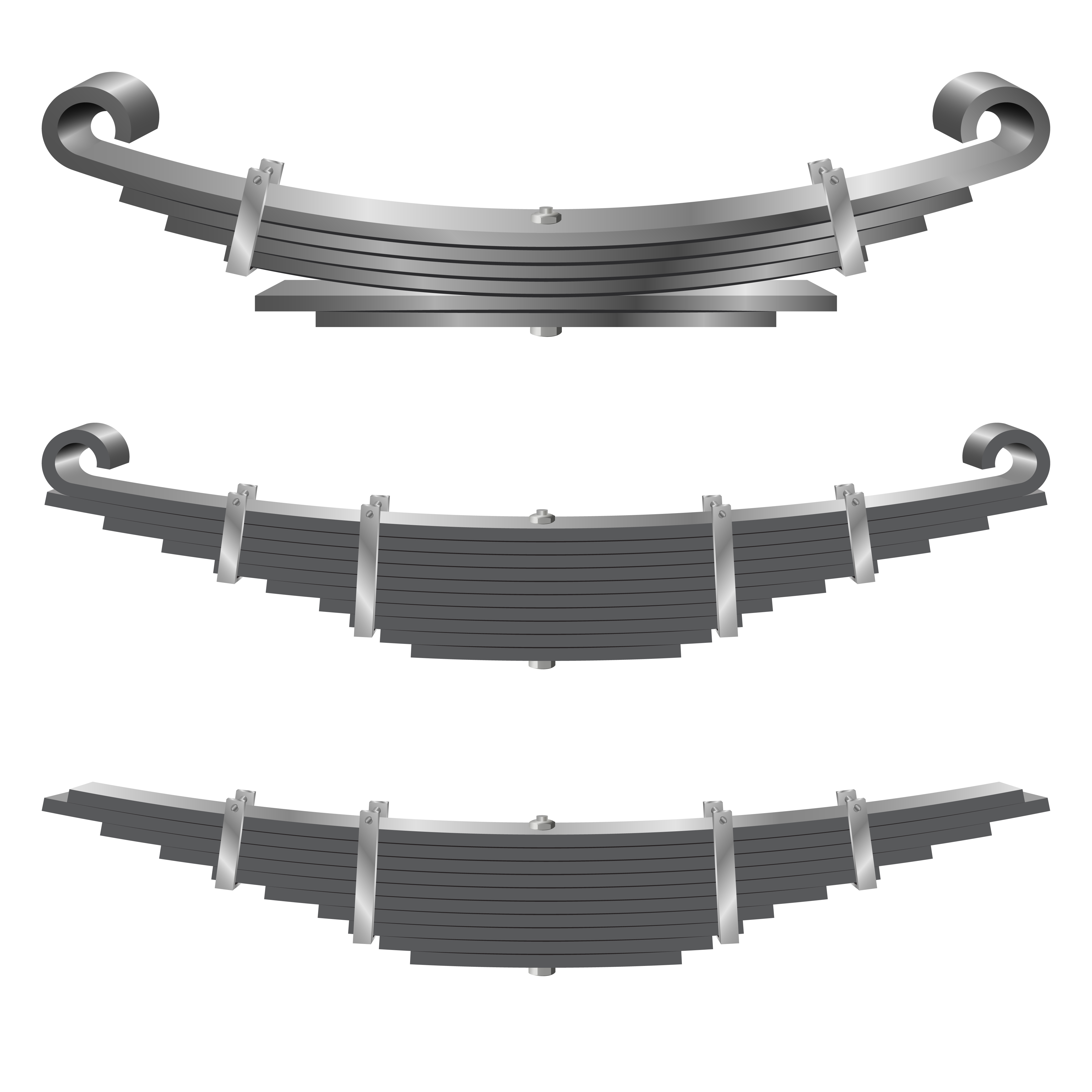

Nowadays it is hard to imagine how uncomfortable transport must have been in the era of coaches. Not only were streets everything but smooth and even like they are now. Vehicles were equipped with very rudimentary suspension. The fantastic constructions of leather straps and leaf springs were prone to make you seasick rather than comfortable. Traditional solutions for comfort enhancement were at any rate not suitable for cars. A need for new, more compact solutions developed. Furthermore they had to be particularly adaptable to cars gradually becoming quicker.

Initially, leaf spring were used. They are cheap and simple in production as well as very reliable. Therefore, they can still be found on the rear axle of commercial vans. Soon they were complemented by oil-pressure shock absorbers, which were able to absorb minor bumps.

Initially, leaf spring were used. They are cheap and simple in production as well as very reliable. Therefore, they can still be found on the rear axle of commercial vans. Soon they were complemented by oil-pressure shock absorbers, which were able to absorb minor bumps.

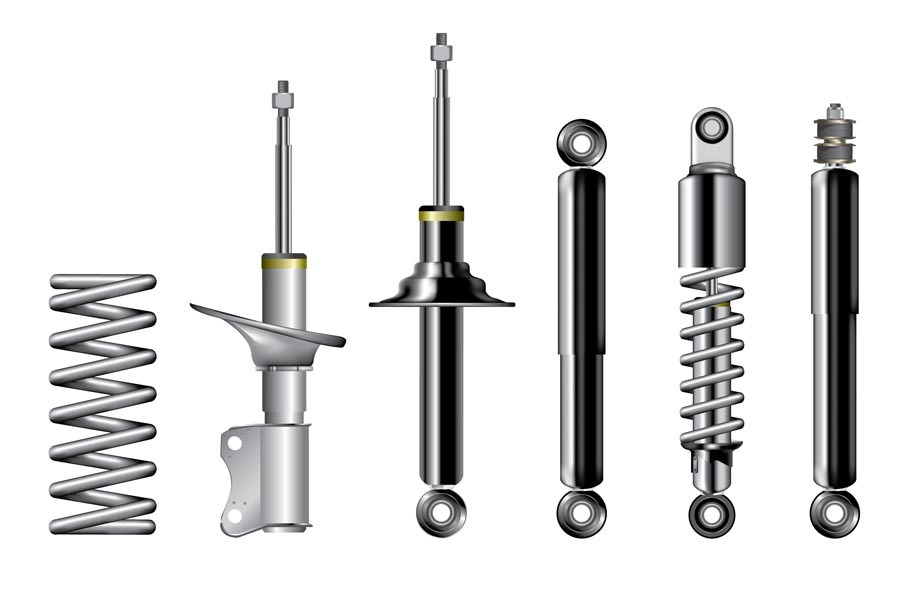

With the introduction of spiral coils, suspension struts became as compact as was required for modern vehicles. Oil-pressure shock absorbers are nowadays only used occasionally. Mainly front forks of motorcycles are still equipped with this damping solution.

With the introduction of spiral coils, suspension struts became as compact as was required for modern vehicles. Oil-pressure shock absorbers are nowadays only used occasionally. Mainly front forks of motorcycles are still equipped with this damping solution.

Gas-pressure shock absorbers are nowadays standard for cars. Their advantage is their excellent damping performance. Their disadvantage is the fact that they are a typical wear part and need regular replacement. Gas-pressure shock absorbers cannot be repaired.

Gas-pressure shock absorbers are nowadays standard for cars. Their advantage is their excellent damping performance. Their disadvantage is the fact that they are a typical wear part and need regular replacement. Gas-pressure shock absorbers cannot be repaired.

Identifying a defective shock absorber

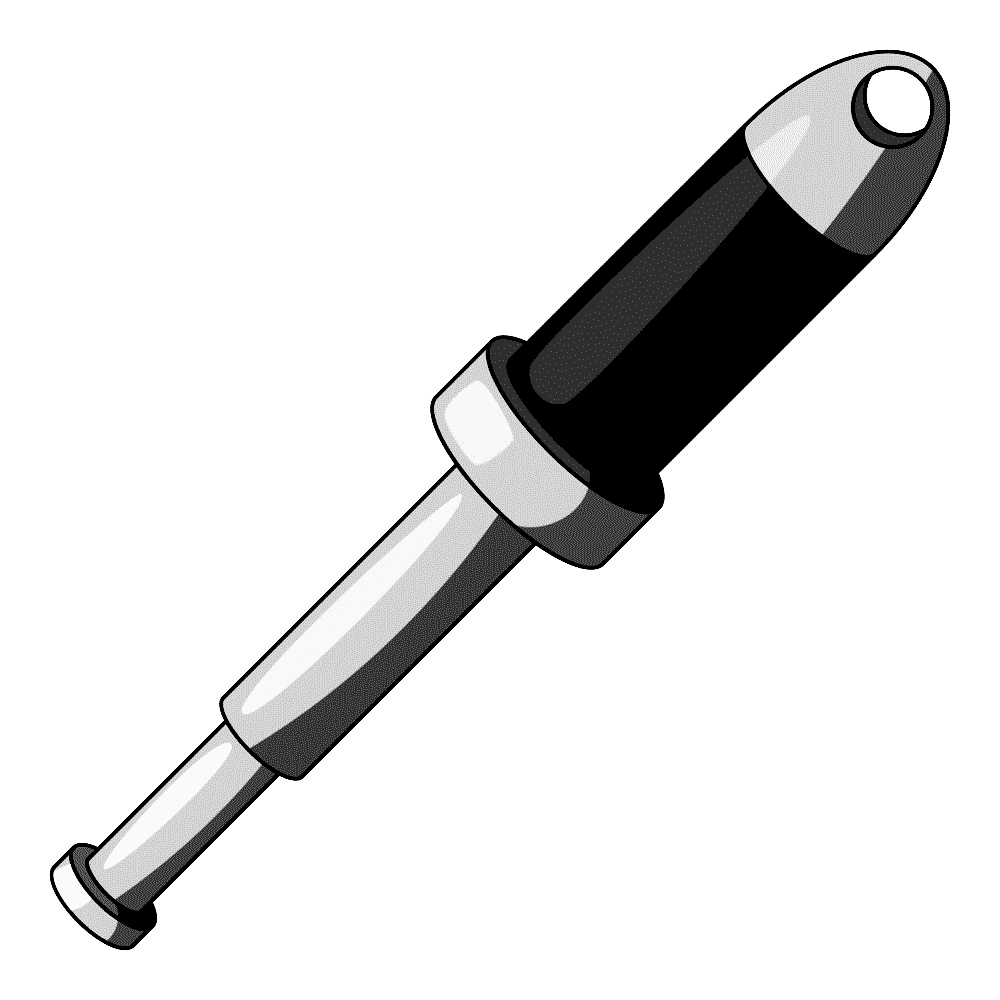

A defective shock absorber has lost its damping effect. The car is now only damped by the spiral coils. When a braking manoeuvre causes the car front to “dive” and strongly rebound, practically no damping is present. This can also be tested on a stationary car: simply press it down at every corner and observe what happens: if the car rebounds repeatedly, the shock absorber is broken.

Shock absorber front-/rear axle Discounteravailable from only £9,33to the shop ⇒ |

A further indication is a clucking noise or oil leaking from the damper. Rattling sounds during driving are an indication of a defective strut bearing. Its replacement requires disassembly of the shock absorbers, which should be replaced on this occasion.

|

Replacing shock absorbers on the rear axle

|

Replacing shock absorbers on the front axle

|

1. Jacking up the car

To safely work on the car it should be in a secure position. The special safety stands are most suitable. Blocks of woods, bricks or a single hydraulic jack constitute a considerable risk of accident. Always use suitable tools. The car should always be hoisted on the provided contact points. Faulty positioned jacks can cause severe damage to the bodywork. |

2. Dismounting wheels

|

3. Disengaging the shock absorber from the wheel

4. Disengaging connected components

|

5. Disengage strut bearings

|

6. Suspension renewal

Clamping the spring gives access to the shock absorber. The spring plates are unscrewed, and the damping unit can be pulled out. The correct installation direction is marked with an arrow. IMPORTANT: For installing the new shock absorber no impact wrench should be used as it might loosen the ring seal. If this remains unnoticed, the strut absorber might disintegrate during driving, potentially causing a dangerous situation. A shock absorber replacement implies the replacement of the strut bearing. |

7. Further repairsEverything is assembled in the reverse order. Now, the shock absorber on the other side should be replaced as well. Principally, all front axle components are always replaced in pairs. This applies to brakes, steering knuckles, ball joints and tie rods. As these components have to be disassembled or removed in case of shock absorber replacement anyway, they should be profoundly checked prior to assembly. If the components approach their wear limit, this is an excellent occasion for preventive replacement. By all means take a look at the inner and outer axle sleeves. If they are torn or porous, they are up for replacement as well. This specifically applies if grease is leaking out. This means a bit more work. On the other hand you now have a completely new front axle at little expense. |

New shock absorbers offer comfort and safety

New shock absorbers offer comfort and safety

With freshly replaced shock absorbers the full driving safety is restored. The car can be kept under control more easily and is considerably more comfortable to drive. It maintains its track better and no longer swerves. This is noticed immediately after installation of the new dampers. Therefore keeping an eye on the dampers is a sensible measure. A check at every 30.000 – 50.000 km can protect you against nasty surprises.

Foto: wavebreakmedia, Babich Alexander, Viktor Chursin, mhlam, (Rvector), BACHTUB DMITRII, AppleDK, Timofeev Vladimir, Etaphop photo, Roman Samborskyi, chanonnat srisura, Jimmy Yan, Vereshchagin Dmitry / shutterstock.com

Caution, mortal danger!

Caution, mortal danger! Replacing shock absorbers on the rear axle is relatively simple. Spring and damping unit are often installed separately. The car should be sufficiently jacked up until there is no pressure on the rear axle, i.e.

Replacing shock absorbers on the rear axle is relatively simple. Spring and damping unit are often installed separately. The car should be sufficiently jacked up until there is no pressure on the rear axle, i.e.  The front axle is generally equipped with suspension struts in which the damping unit is integrated within the spiral coil. Removing them is somewhat more complicated.

The front axle is generally equipped with suspension struts in which the damping unit is integrated within the spiral coil. Removing them is somewhat more complicated. Prior to jacking up: loosen the wheel nuts

Prior to jacking up: loosen the wheel nuts Prior to jacking up, the wheel nuts are loosened. Now they can be unscrewed more easily.

Prior to jacking up, the wheel nuts are loosened. Now they can be unscrewed more easily. The shock absorber is mounted on the wheel suspension with two bolts. If these are too tight, a bit of penetrating oil (e.g. WD-40) can help here.

The shock absorber is mounted on the wheel suspension with two bolts. If these are too tight, a bit of penetrating oil (e.g. WD-40) can help here. The brake hose, cable of the wear indicator and the ABS sensor are disengaged and put aside with cable ties. In order not to separate the brake circuit, the brake caliper can be unscrewed and hung aside. This considerably simplifies the disassembly of the shock absorber.

The brake hose, cable of the wear indicator and the ABS sensor are disengaged and put aside with cable ties. In order not to separate the brake circuit, the brake caliper can be unscrewed and hung aside. This considerably simplifies the disassembly of the shock absorber. The shock absorber is now connected to the bodywork by the strut bearing. The covers are removed with opened bonnet, enabling unscrewing the bolts underneath.

The shock absorber is now connected to the bodywork by the strut bearing. The covers are removed with opened bonnet, enabling unscrewing the bolts underneath. If you don’t have the proper tools for clamping the strut, the entire component can be replaced. Spring coils are subject to wear as well. A complete suspension strut with spiral coil and shock absorber is considerably easier to replace. Furthermore this establishes a new condition of the suspension.

If you don’t have the proper tools for clamping the strut, the entire component can be replaced. Spring coils are subject to wear as well. A complete suspension strut with spiral coil and shock absorber is considerably easier to replace. Furthermore this establishes a new condition of the suspension.

(8 votes, average: 3.50 out of 5)

(8 votes, average: 3.50 out of 5)